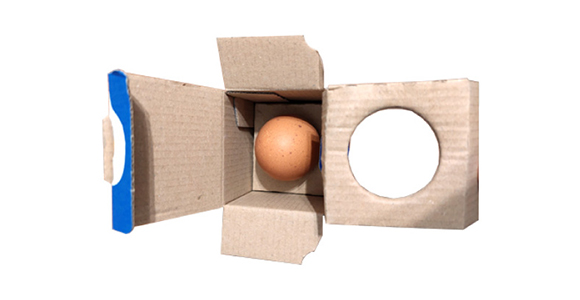

How a single egg box design changed everything

When it comes to fresh food delivery, protection is key. Even more so when you’re dealing with eggs – like our client, an online retailer of meal kits, that needed to pack individual eggs. Antalis Packaging redesigned a new egg box, which won the Silver Award at The Grocer Packaging Awards!

When it comes to fresh food delivery, protection is key. Even more so when you’re dealing with eggs – like our client, an online retailer of meal kits, that needed to pack individual eggs. Antalis Packaging redesigned a new egg box, which won the Silver Award at The Grocer Packaging Awards!

The client's challenge

The company's existing packaging for individual eggs was a hand-assembled die-cut-box that took approximately 40 seconds to assemble and pack. With sometimes over 8,000 eggs being sent out a week, this method was both laborious and costly.

The Antalis solution

Using a clear framework, the Antalis packaging team worked to identify a solution, coming up with a moulded, self-locking, pulp-based box that can be assembled and packed in under 10 seconds.

The process

- 1. Exploration: Antalis visited the company's packing operation to assess the current situation and process. The original box used to protect the eggs was made from die-cut corrugated kraft, and was time-consuming to assemble and pack. Four people a day were required to meet the demand.

- 2. Proposition: Because both Antalis and the client share sustainable values, the team took into account multiple parameters, and put forward 8 different solutions, all of which offered significantly improved performances than the existing solution. The material chosen was 100% recycled, compared to the virgin kraft of the original pack. The replacement pack was also 20% lighter in material use and offered 25% more units per pallet.

- 3. Test: Different tests were made to ensure Antalis’s proposed new method ticked all the client’s boxes. Transit trials showed a success rate of over 98%, while the chosen solution took under 10 seconds to assemble and pack.

- 4. Implementation: The new individual egg box has now been fully implemented in our client's warehouse.

“Packing hen's eggs for safe transit was one of the most challenging projects I have worked on, but the results we achieved for the client made every effort worthwhile. Our team’s ability to take a brief and deliver a concept that not only met every requirement, but also surpassed the client’s expectations, was incredible and hugely satisfying.

Whenever we, at Antalis, work on new packaging solutions, sustainability is always a key criterion, so it is always pleasing (as in this instance) when we get to work with a client who shares these goals. The chosen solution wasn't the cheapest up front, but it was by far the most sustainable and, in fact, delivered the greatest savings overall.”

— Stacey McDonald, Packaging Account Manager - Antalis UK

Advantages

Time-saving

A moulded, self-locking egg box that cuts assembly and packing time by 75%.

Environmentally-responsible

A pulp-based egg box that reduces material use by 20% and allows 25% more units per pallet.