Discover our innovative Paper Stretch Master’in Performance

Because our customers are just as concerned about the environmental impact of their activities as we are, our team of experts joined forces with a paper manufacturer to co-design an efficient wrapping paper-based solution.

Because our customers are just as concerned about the environmental impact of their activities as we are, our team of experts joined forces with a paper manufacturer to co-design an efficient wrapping paper-based solution.

A resourceful material

Rather than trying to invent something new, we wanted to find new and innovative ways to use a trusted, existing material. We did this by using crepe paper to create high-performance wrapping rolls. Despite appearances, the crepe paper used for our Paper Stretch Master’in Performance is flexible enough to stretch, and thus resist tearing, when goods are being packed (more on this later).

We used the best Nature had to offer: a mono-material product made from 100% paper fibres, without any coating (no glue, no PE) – making it completely recyclable and easily disposed of in the waste paper stream.

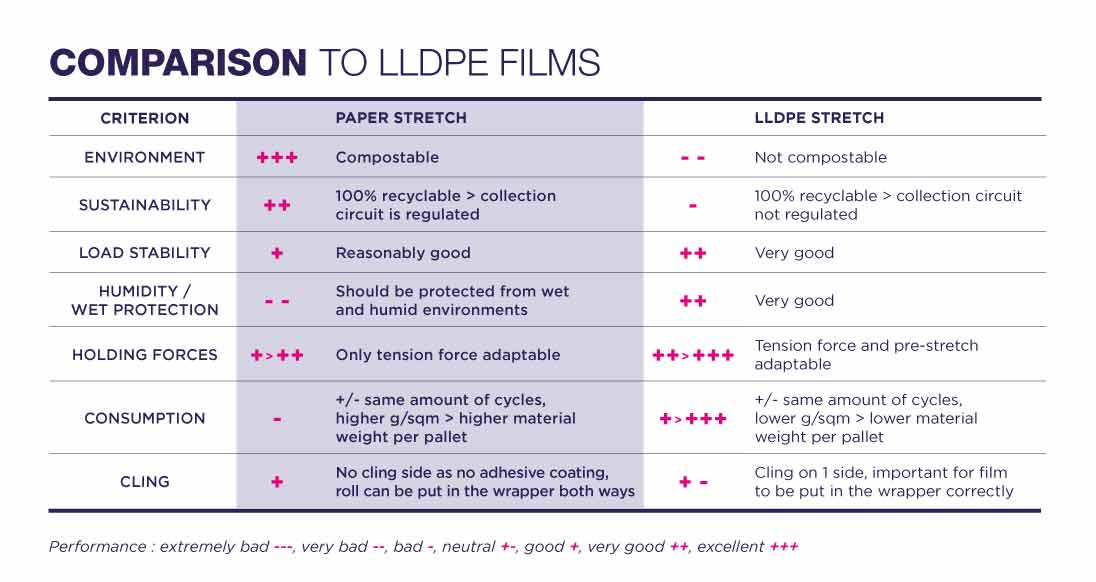

To help you better understand the characteristics of this material, here’s a table that compares our Paper Stretch solution to plastic:

For the simplest use

Now you know a little bit more about this Paper Stretch Innovation, you’d probably like to know how it works. Don’t be surprised if we tell you, it’s as easy to use as its composition is simple.

And because a picture is worth a thousand words:

- NO adhesive dots or coating is needed between the layers of paper.

- NO special machinery needed either. It works on both semi-automatic and automatic wrapping machines.

- NO need for a special dispenser, as manual rolls fit standard devices.

Is this product for you?

We know this innovative Master'in product is going to turn some heads. And our priority is for your package to be wrapped safely so that it can be delivered in its original shape. Here, therefore (as promised), is a list of the main situations it will be suitable for.

We recommend that our clients use it on lightweight pallets (around 300 kg), no taller than 120 cm, with low inertia forces. The paper stretch Master'in Performance will also work best on pallets that do not have huge voids.

Now for the shipment conditions: We recommend using it for direct shipments only (from sender to receiver). It works wonderfully for in-house storage (notably for dust protection), and as an intra-logistic solution. And finally, as with all paper, it is recommended for use in dry areas only (as in humid areas, the paper might deteriorate over time).

Our final thought

If necessary, you can always combine the Paper Stretch with an additional layer of protection, like anti-slip paper, corner protection or strapping, to boost its resistance, and run some internal tests before shipment. But overall, this solution has been test-proofed at Antalis Packaging, and if used in the right conditions, will be very effective.

So there you have it! Another innovative Antalis’ solution that will satisfy anybody looking for more sustainable packaging, and an alternative to plastic stretch films.

Interested to test it?

Contact our experts to book a test session : [add link to the Paper Stretch campaign dedicated landing page form]

[add name, title, mail address and phone number of local stretch film expert]