How sustainable packaging can boost experience

How thoughtful, sustainable packaging design has reduced breakages of glass bottles in transit and improved customer experience.

How thoughtful, sustainable packaging design has reduced breakages of glass bottles in transit and improved customer experience.

The client's challenge

Our client conducts a business with a strong environmental ethos – one of its aims is to help reduce reliance on single-use plastics through the sale of refillable glass and plastic bottles to spas, hotels, self-catering accommodation, and lifestyle, zero waste and general retail shops around the world.

To protect bottles during transit, the client had been using corrugated sheeting to wrap the bottles before packing them into transit cartons with additional void fill. As well as being time consuming to pack, dust and debris from the packaging often clung to the bottles.

They turned to the team at Antalis Packaging for help in finding a solution. They required a box that would offer both the protection and presentation of the bottles in line with its environmental stance.

The Antalis solution

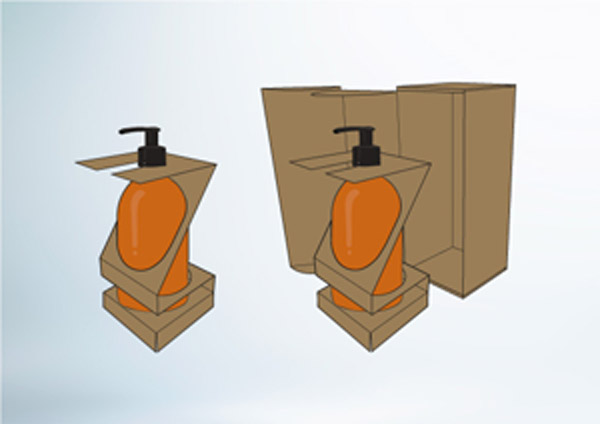

A bespoke transit-cum-presentation box that would accommodate three different bottle sizes - 1,000ml, 750ml and 500ml. Three sizes of suspension insert, one for each bottle size, holds the bottle secure and away from the external packaging wall. Made from recycled/recyclable B-flute corrugated board. A small branded sticker holds the box closed.

"We asked for a box to secure our glass products, which come in a variety of sizes. The challenge was to create an aesthetically pleasing box to protect the product and reduce unnecessary packaging. The final design created was great as internal fittings were designed and created to fit all our products reducing the need for many box sizes and only needing to change the internal design. This was a simple clever design which would save us on costs."

OUR CLIENT

The process

Using a clear framework, the Antalis packaging team set to work developing a solution:

- 1. Explore: Antalis visited the client’s site to gain a full understanding of the requirement. It was important to the company that they minimise use of packaging materials and avoid any unnecessary printing. In addition to providing protection, they required packaging that would double up as display packaging on retail shelving, and that would maximise efficiency and minimise storage space.

- 2. Propose: The team at the Antalis Smart Packaging Centre devised a one-piece universal outer box that would accommodate all three bottle sizes, with a one-piece suspension insert in three size options to hold the bottle securely in place without making contact with the outer packaging. Both elements of the packaging would be made in a B-flute corrugated board. To minimise environmental impact and resources, a small, branded sticker was proposed to seal the boxes shut.

- 3. Test: Drop tests were carried out with a success rate of 100%.

- 4. Implement: The proposal has now been fully implemented.

Advantages

Cost-saving

No bottles have been damaged in transit since implementing the new packaging. No need for separate display packaging.

Environmental

Materials used are made from recycled paper and are 100% recyclable.

Customer experience

Bottles arrived with customers undamaged, free from debris and, where appropriate, ready to display.