How bespoke design cuts carton assembly time by more than 60% ?

One of our clients, who happens to be a car parts shipper, wanted a packaging solution that could both meet transit requirements and remain quick and easy to assemble. Not only was our solution more secure, it also saved them an impressive amount of time.

One of our clients, who happens to be a car parts shipper, wanted a packaging solution that could both meet transit requirements and remain quick and easy to assemble. Not only was our solution more secure, it also saved them an impressive amount of time.

The customer’s challenge

This client ships overseas, so it was really important to them that the packaging be both strong enough to withstand the journey and protect the parts, ensuring that they arrived in pristine condition.

They already had an existing solution, which — although sufficiently sturdy — was time-consuming and difficult to assemble, requiring heavy duty staples to rigidify the box and hold the individual dividers in place, which presented a health and safety issue.

The Antalis solution

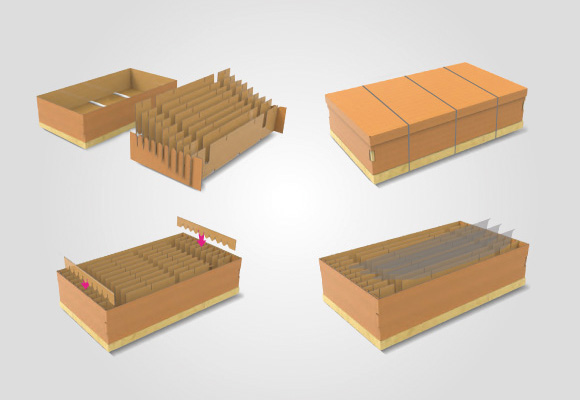

Using a clear framework, the Antalis packaging team worked to develop a bespoke box design solution, including dividers that were die cut to incorporate slots. As well as eradicating the need for staples, they also ensured that the box and dividers couldn’t be assembled incorrectly.

The process

- 1. Exploration: A packaging technologist from Antalis' Smart Packaging Centre visited the client's site to gain a clear understanding of their requirements and assess the existing solution.

- 2. Proposition: Antalis' packaging technologist designed a solution that could be assembled without the use of staples, the most time-consuming aspect of the assembly process. It was also designed to eliminate the issue of incorrect assembly, and with a lighter-weight corrugate, reduce the use of materials and associated transport costs.

- 3. Test: Two samples were made so the customer could test the ease of assembly. One of the cartons was packed and shipped to another site to assess how well it withstood the transit process.

- 4. Implementation: After a successful test, the carton was implemented at the client's site. To support the transition to the new carton, we created and supplied a step-by-step guide for the packers.

"While the original carton worked well in terms of protecting the products during transit, each internal divider had to be stapled in place, which posed significant challenges during assembly. By introducing internal dividers that had die-cut slots, we were able to significantly reduce assembly time."

Todd Smith

Antalis Packaging Technologist

Advantages

Time saving

The bespoke design reduced carton assembly time from 12.5 minutes to 4.5 minutes.

Environmental friendly

A packaging designed to optimise the quantity of carton, thus reducing the weight of the package and ultimately, the ecological impact of transport.

Safe manipulation

Without staples, not only is the package easier to recycle, it also eliminates the associated risks.