How to transport heavy battery modules?

A manufacturer of high-performance battery modules needed a packaging system that would ensure its heavy products arrived at their destination intact. Our experts at Antalis developed a bespoke solution for them.

A manufacturer of high-performance battery modules needed a packaging system that would ensure its heavy products arrived at their destination intact. Our experts at Antalis developed a bespoke solution for them.

The client

A manufacturer of high efficiency battery modules turned to Antalis to help find a packaging system that would keep its products secure during transit.

The challenge

The brand needed us to design a packaging solution that would protect their heavy battery modules during transit by preventing the risk of tipping.

To ensure the products arrived intact, they needed the following:

- Stabilise 10 battery modules weighing 80 kg each during overseas shipping

- Separate modules to prevent contact damage during handling

- Maximise container saturation

The Antalis solution

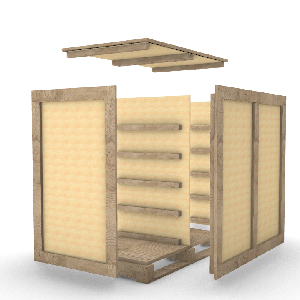

The Antalis packaging team developed a custom-made, high-capacity, stackable storage system with both guides to lock battery modules in place and anti-tipping pallets for extra stability.

The bespoke platform was entirely made of wood, with a frame and base in HT-treated fir and pine plywood panelin for sturdiness.

It also had an ISO container, sized and mounted on 2-way anti-tip pallets for stability. Being entirely stackable, with modules arranged in two stacks side by side, the designed solution allowed for an even distribution of weight on the platform and could support a total of 1,600 kg.

The entire structure was nailed in place, except for the front side, which—fixed by metal clips—was removable so that the contents could be loaded and unloaded easily. Our designers structured the inside of the container with guides designed to keep the battery modules horizontal, locking them in place separately to prevent load displacement during transport, and avoid scratches and rubbing.

The platform was a seemless fit for the headboards and sides, and flush to the ground, making the package a single volume, with no overhangs or scope for load movement.

Advantages

Simplicity

The design platform was specifically designed for easy handling.

Safety

The bespoke design was conceived to prevent the risk of tipping over.

Space saving

Its dimensions were calculated for maximum container saturation.

Services provided

With the right expertise and guidance, we helped our client to optimise their packaging process efficiency.

We designed a bespoke solution that ticked all our customer's boxes and helped them to overcome their specific problems