Eco-responsible packaging: 4 growing trends in 2024!

In response to shifting customer preferences and a growing emphasis on environmental responsibility, businesses are increasingly adopting eco-responsible packaging.

However, the ongoing research goes beyond conventional sustainability, aiming to actively rejuvenate and replenish our natural resources. This is where regenerative packaging comes in.

In response to shifting customer preferences and a growing emphasis on environmental responsibility, businesses are increasingly adopting eco-responsible packaging.

However, the ongoing research goes beyond conventional sustainability, aiming to actively rejuvenate and replenish our natural resources. This is where regenerative packaging comes in.

The increasing environmental impact of plastic pollution in Europe

According to an OECD report¹, the world is producing twice as much plastic waste as two decades ago, with the bulk of it ending up in landfill, incinerated or leaking into the environment.

Under business as usual, as the use of plastics increases in the coming decades, so too does global plastic waste, rising from 353 Mt in 2019 to 1014 Mt in 2060.

In March 2022, more than 170 countries agreed to develop a global treaty to end plastic pollution. This historic treaty will address the full lifecycle of plastics, from production and design to waste management. It will also promote sustainable production and consumption of plastics and encourage the development of a circular economy for plastics.

In addition, the European Commission has proposed new EU-wide rules on packaging to tackle this growing source of waste and consumer frustration. In December 2023, the European Council agreed its negotiating position on new rules for more sustainable packaging in the EU.

On average, each European generates nearly 180 kg of packaging waste per year. Packaging is one of the main users of virgin materials, and 40% of plastics and 50% of paper consumed in the EU are used in packaging. Without action, the EU would see an additional 19% increase in packaging waste by 2030, and this rises to 46% for plastic packaging waste. The new rules will put the packaging sector on the path to climate neutrality by 2050.

There are some revolutionary technologies that can help achieve these goals, including four groundbreaking sustainable packaging trends:

1 - Carbon capture-based packaging

Carbon-capture-based packaging is an innovative approach increasingly being used to help reduce the environmental impact of packaging. Carbon capture technology involves capturing carbon dioxide (CO2) emissions from industrial processes, power plants, or directly from the atmosphere to prevent it from entering the atmosphere. These captured carbon emissions can then be used in various applications, including the creation of materials for packaging. According to experts from IDTechEx in their latest report on Carbon Dioxide Utilisation 2022-2042, there are at least three major processes that can be used to convert CO2 into polymers: electrochemistry, biological conversion, and thermocatalysis. For example, Newlight Technologies², a Californian company, has developed a material called AirCarbon, which is made by capturing carbon emissions from methane and turning it into a polymer.

This material can be used for various applications, including packaging.

Some additives can be incorporated into traditional packaging materials to facilitate the capture of carbon dioxide during production or use. These additives might chemically bind with CO2 or encourage the absorption of carbon emissions during the packaging’s lifecycle.

Some additives can be incorporated into traditional packaging materials to facilitate the capture of carbon dioxide during production or use. These additives might chemically bind with CO2 or encourage the absorption of carbon emissions during the packaging’s lifecycle.

2 - Plant-based packaging

Tetra Pak³ was the first company in the food and beverage industry to produce milk carton packaging made from 100% plant-based polymers, fully traceable to its sugar cane origin. The rise of plant-based packaging materials indicates a significant shift towards more sustainable and eco-responsible alternatives compared to traditional petroleum-based plastics. These materials are sourced from renewable plant resources such as corn, sugar cane, bamboo and other plants, and offer several advantages that contribute to a reduced carbon footprint and a more sustainable future.

By using plant-based materials, companies can help to reduce greenhouse gases and offset their carbon footprint.

Many plant-based packaging materials are designed to be biodegradable or compostable.

This means they break down naturally over time, reducing the environmental impact associated with persistent plastic waste. For example, plant-based materials are now used for packaging in many industries, including pharmaceuticals, beauty products, personal care, electronics and construction materials, where they are replacing conventional plastic packaging. These biodegradable options minimise waste and environmental harm.

Numerous plant-based materials can be used in the packaging industry, such as bio-based plastics made from organic materials like corn, sugar cane and potato starch, to create biodegradable and compostable food packaging; cellulose, a natural polymer found in plant cell walls; plant fibres, such as bamboo and wood, used to reinforce traditional paper or cardboard; and bagasse, a by-product of sugar cane processing, which is particularly suitable for use in food service items such as plates and bowls.

3 - Mycelium technology

Mycelium, the root system of mushrooms, has gained attention as a sustainable and biodegradable alternative for packaging materials, forming a dense and durable material with unique properties to create environmentally responsible packaging solutions.

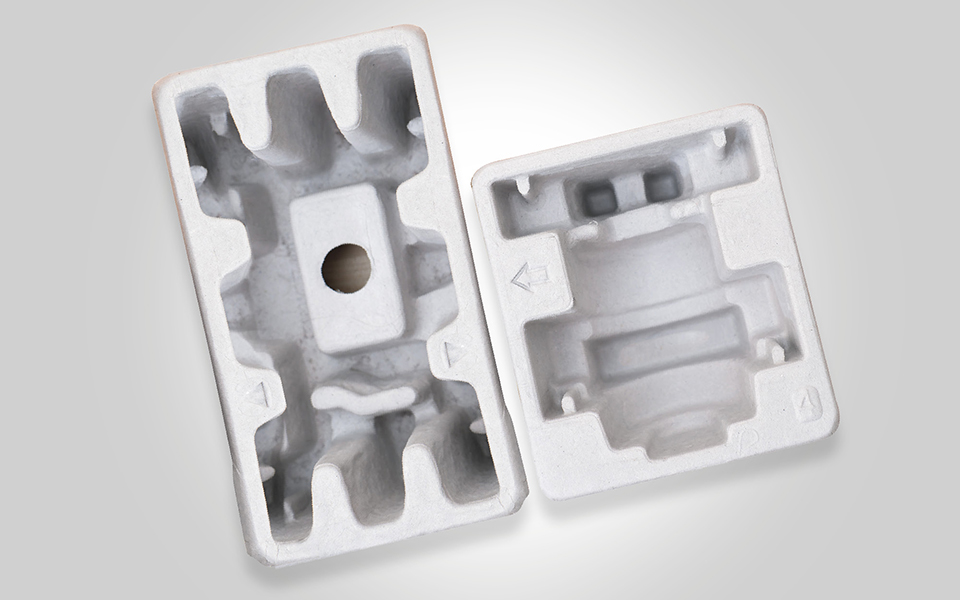

The mycelium-infused substrate can be moulded into various shapes, creating custom packaging designs for different products. Mycelium-based packaging is lightweight yet strong and durable. It offers the protective properties of traditional packaging materials such as foam, making it suitable for protecting fragile items, for example electronic devices, during transportation. Mycelium has natural insulating properties, offering an additional advantage for products that require temperature control during shipping and the capability to protect perishable goods during transit. In addition, mycelium-based packaging is fully biodegradable and compostable.

For example, Teaching Machines⁴ (specialised in innovative audio hardware) collaborates with Magical Mushroom Company® to protect its Wellspring audio hardware. They use eco-responsible Mushroom® Packaging made from mycelium. This sustainable packaging ensures safe transportation while reducing plastic waste, aligning with Teaching Machines' commitment to environmental responsibility.

This partnership proves that it is possible to combine practicality and environmental responsibility.

4 - Circular economy practices

In the context of packaging, several key principles contribute to a circular economy, such as designing for recyclability, using recycled content, encouraging reuse and reducing single-use waste or collaborating across the supply chain.

Packaging should be designed using materials that are easily recyclable and have established recycling streams. The materials should also be simplified by using single materials or materials that are easily separable for recycling. Complex multi-layered materials can be challenging to recycle and may end up as waste.

Integrating recycled content into packaging materials establishes a closed-loop system in which materials are collected, recycled and then reused to manufacture new products. This helps to reduce the demand for virgin resources. By incorporating recycled content into their packaging, companies contribute to the demand for recycled materials, fostering a more sustainable supply chain. Collaboration across the supply chain, including manufacturers, retailers and waste management facilities can help create efficient systems for collecting, sorting and recycling materials.

Amazon⁵, for example, has committed to using 100% recyclable or reusable packaging by 2025. The company is also investing in innovative packaging solutions such as its Amazon Frustration-Free Packaging programme, which uses 95% packaging that can be easily flattened and reused. In addition, Amazon⁵ has partnered with the Recycling Partnership to improve recycling infrastructure in the US, making it easier for customers to recycle their packaging.

Conclusion

The adoption of regenerative packaging practices signifies a pivotal shift towards sustainability and a more responsible packaging industry. By embracing these innovative trends, Antalis is not only aligning itself with evolving environmental expectations, but also setting a commendable standard for sustainable packaging solutions in the industry.

Sources :

*1 Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options, OCDE, june 2022

*4 https://magicalmushroom.com/mushroom-packaging/case-studies/electronics/teaching-machines

*5

https://www.aboutamazon.com/news/sustainability/how-amazon-is-investing-in-a-circular-economy