Automated Packaging Systems

Packaging automation is perfect when you have a fast-paced packaging operation and are shipping items of different shapes and sizes at high volumes. For example, with an e-commerce business, there's an emphasis on fast turnaround times. Quick, efficient packaging helps you meet those targets, keep your customers happy and avoid backlogs in your despatch area. Automated packaging can also give staff members more time to complete other activities.

![]()

Use less packaging materials

Using an automated system ensures products are packed to a consistently high quality, reducing the need to replace items or waste incorrect or poor packaging. Our automatic packing machines also eliminate the need for void-fill by creating right-sized packaging.

![]()

Cost saving

There are many automated packaging solutions designed to speed up the packaging process, freeing up workers to perform other tasks and in turn reducing costs. Machines are also designed to create right-sized packaging which allows you to save money on void fill materials and shipping costs.

Reducing carbon footprint

Investing in packaging automation will reduce your carbon footprint. Right-sized packaging is not only cheaper to ship, but it also allows you to fit more packages on a pallet or a delivery van, meaning fewer emissions produced from shipping. Waste is also reduced, as the machines are programmed to use 'just enough' material, compared to manual packing.

![]()

Space saving

Packaging automation can save valuable space in your warehouse by eliminate the need to store bulky void fill material or excess packaging. By creating more space in your warehouse, you can improve pick/pack timings and on-site efficiency. The quick speed of the machines means products are sent out on time, which leads to fewer products waiting for shipping and reduces the space needed for delivery backlogs.

Machines

PACjacket automated system

The PACjacket automated packaging system is designed to produce bubble mailers to the exact size of the product being delivered. The system is 400-500% quicker then manual packing, producing an impressive 15-20 bags per minute. The high-quality seals mean you can pack your items with confidence.

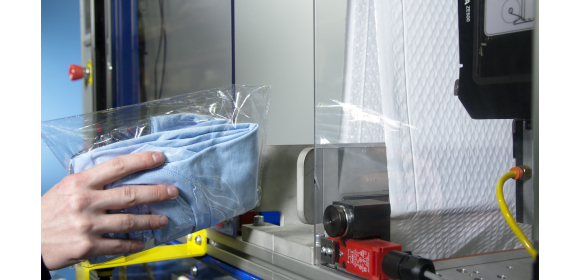

Pregis - automated bagging systems

If you are looking for a reliable and flexible poly bag solution, the Pregis automated bagging system could be the system for you. The durable and flexible automatic and semi-automatic bagger comes with predictive maintenance technology to ensure minimum downtime.

Sealed air - priority pack

The Priority Pack can produce up to 15 ready-to-ship parcels per minute - making it ideal for businesses that ship around 750-1000 single orders in small packages each day. The machine can integrate easily into existing product lines.

We stock a range of consumables for our packaging automation, please contact us for more information.

Case studies

Pacjacket helps a leading UK retailer

Discover how the Pacjacket automated system helped a UK-leading retailer. There had been a lot of investment into carton automation, however, smaller items were bagged by hand - until the introduction of the machine which can bag up to 20 bags per minute!

Our services

Smart systems

Our team of dedicated packaging machinery experts and engineers are available to answer any questions you have regarding your machinery, systems, and packaging automation. If you are new to automated systems and machinery or looking to improve your current solution, our experts are here to help.

stretchCONSULT

Why not take advantage of our free stretchCONSULT service? Our engineers have experience in solving some of the most complex packaging challenges, including looking at ways to better optimise your film usage to save time, money and cut waste. Our dedicated Stretch Film specialist is here to advise you on the best options for your business.