Pallet stretch wrapping

Introducing Antalis’ range of industry-leading pallet wrappers and stretch wrapping machines. These cornerstones of modern logistics operations are available in both semi-automatic and fully automated configurations and are designed to optimise the preparation of pallets for seamless transit processes. With the capacity to wrap pallets at a rate equivalent to three hand wrapping individuals in a single hour, they represent a significant leap in efficiency and effectiveness compared to manual wrapping methods.

Pallet & stretch wrapping machines

Heavyweight pallet wrapper machines are ideal for streamlining operations in high-volume warehouse environments, minimising the need for multiple individual manual wrappers. Our comprehensive range of pallet wrapping equipment includes both semi-automatic and fully automatic stretch wrappers, capable of achieving wrapping speeds of up to 180 pallets per hour. Additionally, we offer manually operated mobile wrapping machines designed to suit the different wrapping needs of all businesses, large and small. These machines not only enhance wrapping speeds but also elevate load stability and ensure consistent presentation, resulting in a more cost-effective process for your operations.

The benefits of stretch wrap

Stretch wrap machines offer a multitude of benefits, enhancing packaging, storage, and shipping processes.

![]()

Package protection

By tightly clinging to items and pallets, stretch wrap applied by an automated machine provides a secure layer, protecting pallets and their contents against dust, moisture, and external elements, reducing the risk of contamination or damage during storage or transit.

![]()

Cost Efficiency

The film employed in our machines undergoes pre-stretching prior to application on the pallet, fortifying its strength and maximising roll usage by up to four times as much.

![]()

Safety

When a stretch wrap machine is used to wrap a pallet, items are secured in a way that helps to prevent injuries in storage facilities and during transportation, ensuring the safety of workers.

![]()

Waste Reduction

Studies indicate that operators frequently damage or overuse film. By employing a wrapping machine, your business can mitigate this issue. Additionally, with the film pre-stretched by the pallet wrapper, you can better optimise film consumption.

Our stretch wrapping machinery

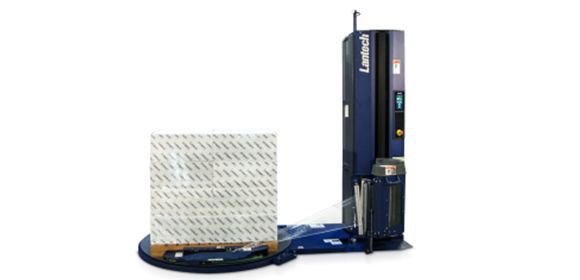

Lantech stretch wrappers

Since 1972, Lantech has been considered a world-leading producer of pallet wrapping machinery and the innovator of turntable and pre-stretch technology. You can be sure of consistent and quality results every time!

Antalis Master'In stretch wrappers

Antalis Master' In stretch wrappers with their versatility and reliability, they are perfect for demanding stretch film applications, with consistently high-quality results.

As well as wrapping machines, we also stock a wide variety of other pallet wrapping tools and accessories. From premium film and pallet toppers to boards and quality edge protectors, we ensure that our stock is tailored to deliver the utmost quality for your packaging requirements.

We can also provide turntables and weigh scales, meticulously designed to complement our pallet wrapping machines. To find out more about our offerings, check out our Packaging Machinery brochure below or alternatively get in touch with our expert team today.

Customer case studies

Walkers transport

Discover how Walker's Transport reduced the damage to pallets in transit after switching from manual to semi-automatic pallet wrapping.

Pet supply manufacturer

Learn how a change of automatic pallet wrapping machine helped a manufacturer of pet supplies reduce costs and waste by an amazing 70%.

Our services

Smart systems

Our team of dedicated packaging machinery experts and engineers are available to answer any questions you have regarding your machinery, systems, and packaging automation. If you are new to automated systems and machinery or looking to improve your current solution, our experts are here to help.

stretchCONSULT

Why not take advantage of our free stretchCONSULT service? Our engineers have experience in solving some of the most complex packaging challenges including looking at ways to better optimise your film usage to save time, money and cut waste. Our dedicated Stretch Film specialist is here to advise you on the best options for your business.