How to optimise a storage warehouse process to gain in productivity?

Our client is a global manufacturer for drives and controls with extreme precision. The manual re-ordering of packaging material was drastically slowing the production down and needed to be automated.

Our client is a global manufacturer for drives and controls with extreme precision. The manual re-ordering of packaging material was drastically slowing the production down and needed to be automated.

The client's challenge

The company purchases 12 different articles. Every 2 days a warehouse employee of the company collects the stock of the articles, fills out an order list by hand and sends it by fax as an order.

The customer wanted the process to be simplified and replenished within 24 hours.

The Antalis solution

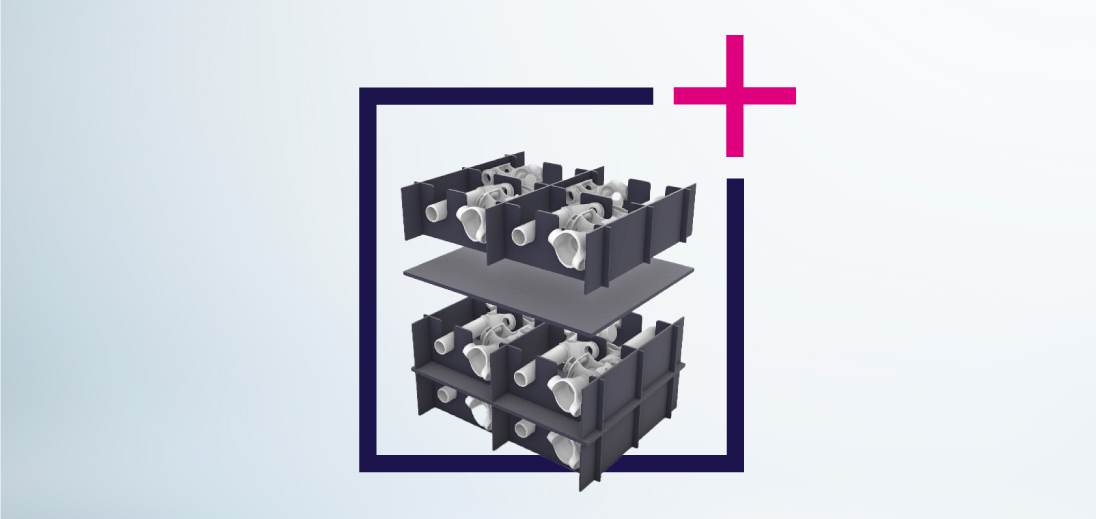

The task was realised with a webcam solution. Every day at 14:30, a webcam takes a picture of a precisely defined area of the customer’s high-bay warehouse and automatically transmits it to Antalis Packaging. The pallet spaces are clearly assigned to the customer articles. An employee at Antalis can see at a glance which articles need to be reordered and triggers a corresponding order. The next day, the goods are delivered to the customer before 14:30 before the next photo is taken. As simple as it is effective: the customer no longer has to worry about his stock and can concentrate on his core business.

Services provided

Related articles

How to develop appealing and smarter packaging?

How to transport heavy battery modules?

Implementation of an e-business solution via webcam.

Implementation of an e-business solution via webcam. Development of an individual logistics concept for inventory monitoring.

Development of an individual logistics concept for inventory monitoring.