How to reduce cost and packing time with consistently high corrosion protection?

A global machine manufacturer, leader in the field of forming technology, wanted to develop an exportable corrosion protection packaging that would be easier and cheaper to manage.

A global machine manufacturer, leader in the field of forming technology, wanted to develop an exportable corrosion protection packaging that would be easier and cheaper to manage.

The client's challenge

The complex classic machine packaging for sea transport, consisting of aluminium composite film in combination with desiccant, is to be replaced by a simpler and cheaper, nonetheless safe solution. The packaging must also be suitable for sea transport to Asia.

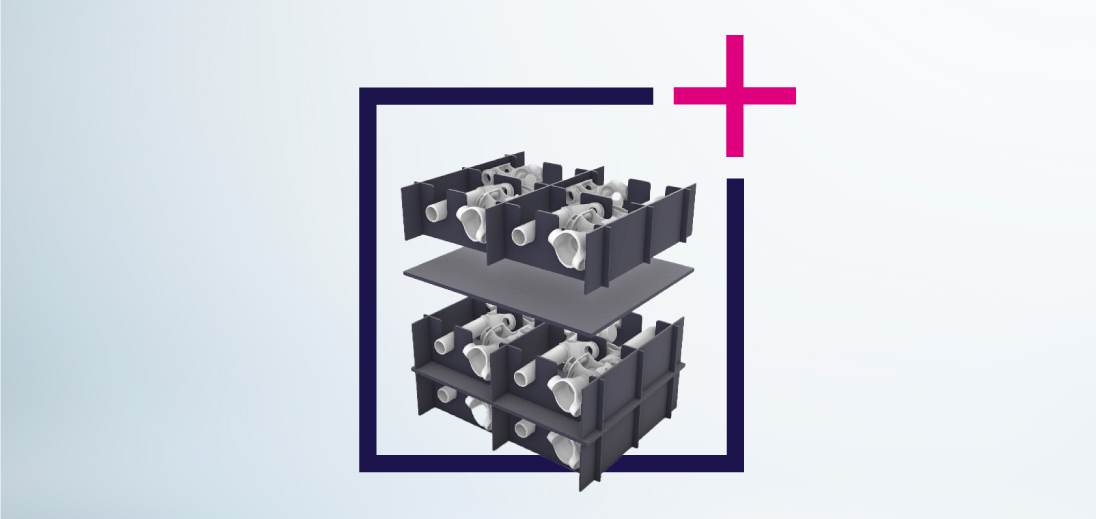

The Antalis solution

A VCI packaging consisting of VCI film and additional VCI deposits in the form of VCI paper and VCI chips, which are placed above and in the machine, has proven to be optimal. The outer packaging does not have to be heat-sealed. This significantly reduces packaging time and costs, whilst the corrosion protection for sea shipment is ensured at the same time. It continues to hold even if the outer packaging is slightly damaged. A quick opening of the packaging (e.g. by customs) is therefore unproblematic: once the packaging is re-sealed, the corrosion protection builds up again.

The process

- Development of the Customer Pain Points and evaluation of the existing packaging in an initial conversation with the customer

- Checking the functionality of the system using a test shipment to Asia by sea freight

- Development of an optimized corrosion protection packaging by product management

Advantages

COST-EFFICIENT

With unchanged corrosion protection during sea shipping, both packaging time and costs are reduced.

TIME SAVING

The metal parts do not need to be greased or de-oiled and are ready for immediate use.

SECURE

Even with minor damage to the packaging or brief opening by customs, secure corrosion protection is guaranteed.

Services provided

Related articles

How to develop appealing and smarter packaging?

How to transport heavy battery modules?